Additive Manufacturing in the Space Exploration Sector

Additive manufacturing has proved its mettle in almost every industry. It is also being used in aerospace especially space exploration for a range of applications. Additive manufacturing will play a key role in shaping the future of space exploration.

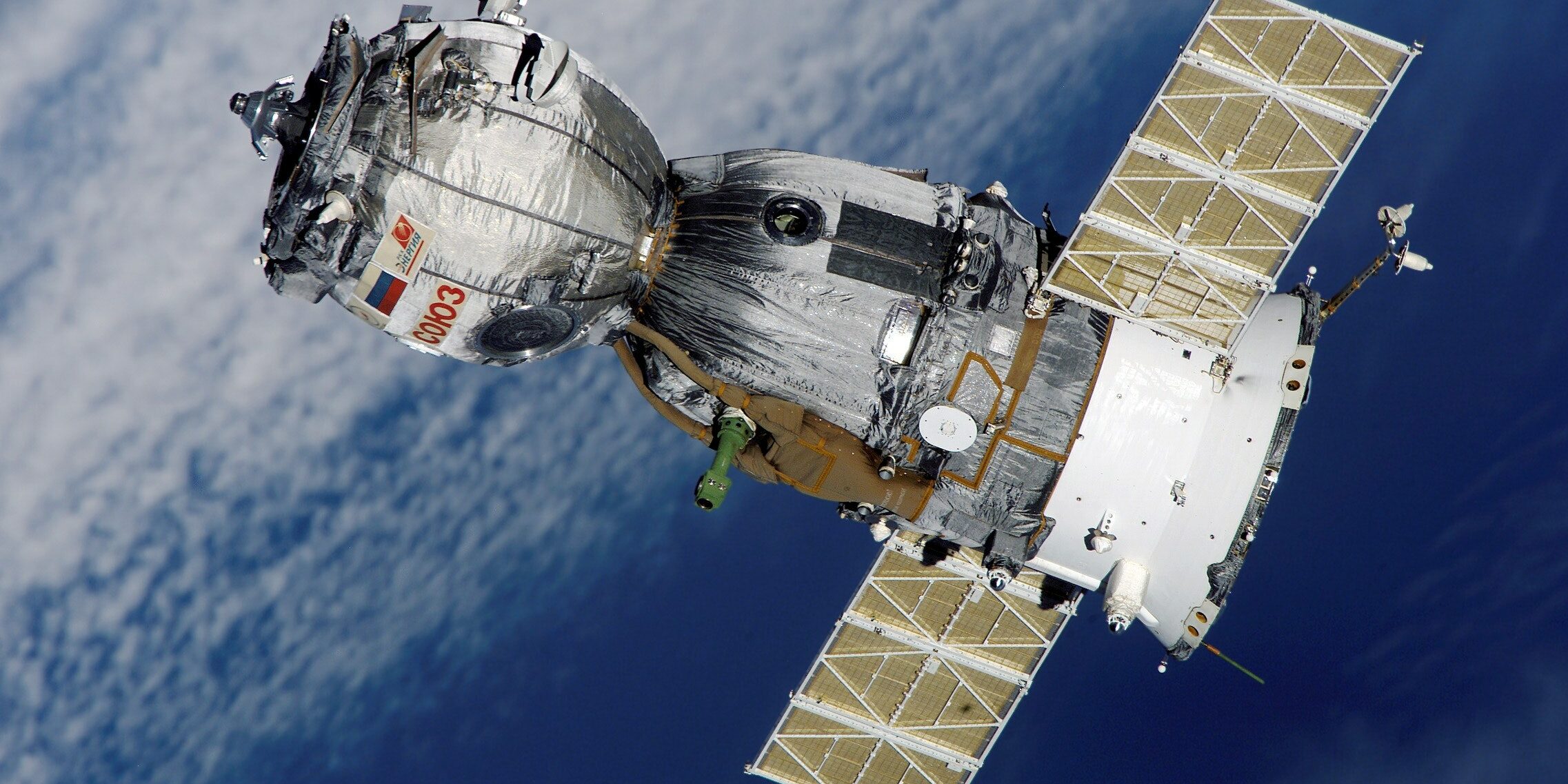

Space agencies around the world are already using additive manufacturing to manufacture low-cost satellites as well as light and efficient rockets.

3D Printing Helps Overcome the Biggest Challenge

The biggest challenge facing organizations involved in space exploration is the extremely high cost per kilogram they incur when a rocket breaks free of the earth’s gravitational pull.

Whether they are looking to place probes, satellites, telescopes or landers, the mission costs can scale up quickly for every additional kilo of payload. A bigger/heavier payload requires a more powerful launch vehicle, thereby shooting up the costs.

Additive manufacturing offers a highly cost-effective solution to optimize the weight of systems used in space exploration. This holds good not only for launch vehicles but also for space-borne devices and systems. In short, 3D printing technology is being used to bring down the cost of commercial space activities considerably.

Small Batch Production

The biggest pain point for satellite and rocketry manufacturing is the difficulty in automating single item and small batch production.

Additive manufacturing offers a practical solution for the space exploration industry especially the commercial infrastructure market. Whether it is the manufacture of spacecraft, ground equipment or in-space platforms, 3D manufacturing has made small batch production a reality.

With space travel becoming common in the future, we envision that additive manufacturing can play a key role. After all, parts may have to be produced in space as well. No other technology makes on-location production and distributed manufacturing of parts as effortless as additive manufacturing can. Additive manufacturing is the answer to the demand for space exploration, getting to orbit, reaching space and staying in space.

The availability of materials like metals in space, or for that matter on the surface of planetary bodies or on asteroids, means it’s possible to build settlements without taking expensive materials from Earth.

TMetal, Your Additive Manufacturing Partner

Here at TMetal, we are excited about the future of space exploration. We strive to stay at the forefront of 3D manufacturing technology through our metal powders that enable metal additive manufacturing a reality for the space exploration sector in Canada. For more information, feel free to get in touch with our team today!