Home / Products / Alloy Powder / Powder Production Equipments

POWDER PRODUCTION EQUIPMENTS

TMetal uses advanced vertical, horizontal, and vacuum gas atomization systems to produce high-efficiency, high-purity metal powders. These processes meet the strict requirements of additive manufacturing, powder metallurgy, and other demanding applications.

Vacuum Gas Atomization

Horizontal Gas Atomization

TMetal’s water atomization system enables large-scale, cost-effective production of high-quality metal powders with controlled particle size. It offers excellent versatility for powder metallurgy, additive manufacturing, and various industrial applications.

Water Atomization

Water Atomization

QUALITY ASSURANCE

Quality control at all stages: before, during and after.

TMetal offers comprehensive testing & analysis and production capabilities with state-of- the-art equipment, ensuring precise and reliable material characterization.

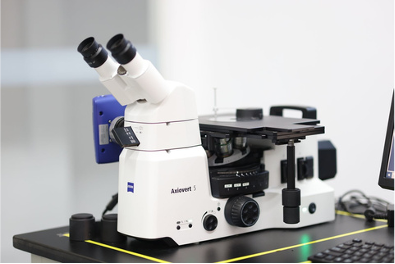

ZEISS Axiovert 5 microscope facilitates detailed material inspections

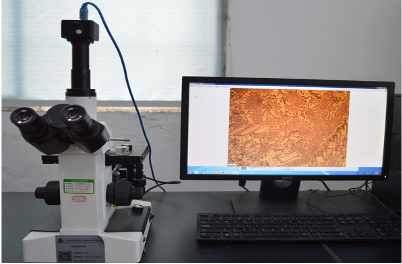

Metallographic microscope 4XC

Shimadzu XRF-1800 performs advanced elemental analysis

AMETEK SPECTROMAXx spectrometer provides high-speed and precise metal alloy analysis

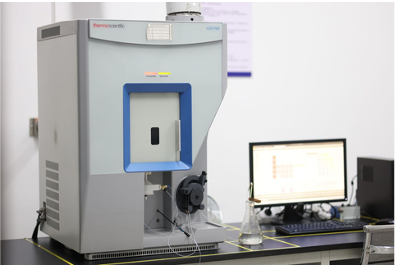

Thermo Scientific iCAP PRO conducts multi-element trace analysis

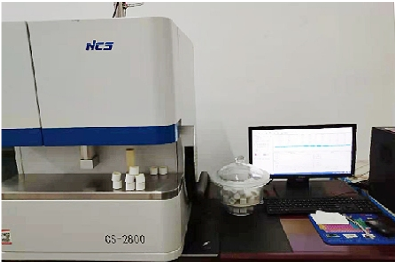

Carbon-sulfur Determinator

ASTM & ISO STANDARDS WE FOLLOW

- ASTM F2792 Standard Terminology for Additive Manufacturing Technologies

- F3049 Standard Guide for Characterizing Properties of Metal Powders Used for Additive Manufacturing Processes

- ASTM B214 Standard Test Method for Sieve Analysis of Metal Powders

- ASTM B822 Standard Test Method for Particle Size Distribution of Metal Powders and Related Compounds by Light Scattering

- ASTM B213 Standard Test Methods for Flow Rate of Metal Powders Using the Hall Flowmeter Funnel

- ASTM B243 Standard Terminology of Powder Metallurgy

- ASTM B527 Standard Test Method for Tap Density of Metal Powders and Compounds

- ASTM E1019-11 by Combustion (Carbon/Sulfur)

- ASTM E1019-11 by IGF (Nitrogen/Oxygen)

- ISO 14707:2000 – GD-OES

- ASTM B212 Standard Test Method for Apparent Density of Free. Flowing Metal Powders Using the Hall Flow meter Funnel