Home / Products / Alloy Rod / Rod Production Equipments

Rod Production Equipments

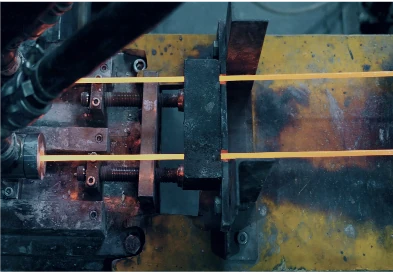

Casting Rod Producton Lines

TMetal’s Casting Rod Production Line produces high-performance cobalt alloy rods for demanding applications such as aerospace engines, gas turbines, and medical implants.

This precision system integrates:

1. Vacuum Melting & Refining

- VIM furnaces (1600–1800 °C) with oxygen control below

10 ppm - Secondary refining via ESR or VAR

- Automated composition control using XRF spectroscopy

2. Directional Solidification

- Water-cooled copper molds with thermal gradient control

- Liquid Metal Cooling (LMC) for single-crystal growth

- Adjustable withdrawal speeds (0.5–10 mm/min)

3. Hot Processing

- Precision extrusion presses (10:1–20:1 ratio)

- Multi-stage hydrogen annealing furnaces

- CNC centerless grinding with ±0.01 mm tolerance

4. Quality Assurance

- X-ray inspection detecting voids ≥ 50 μm

- EBSD for crystal orientation analysis

- Full-length ultrasonic testing for internal defects

This line achieves near-net-shape production with 92-95% material yield, meeting AMS, ASTM and ISO standards for critical applications.