Home / Products / Alloy Powder / HVOF

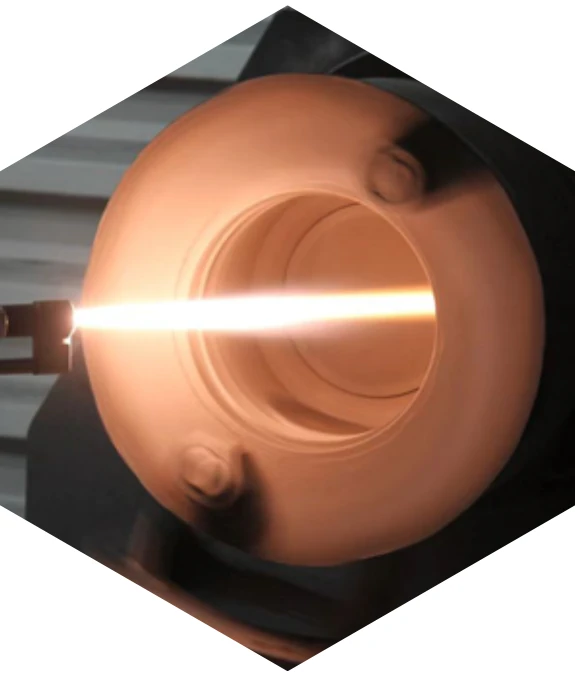

HVOF

In the HVOF process, powder is axially fed into a high-pressure combustion chamber. The exhaust gases exit through a nozzle, creating a high-velocity stream that heats and propels the particles onto the workpiece. This results in a dense, well-bonded coating with minimal heat impact, preserving the properties of both the material and the substrate.

Cobalt-Based Powder

Iron-Based Powder

Nickel-Based Powder

Tungsten Carbide Powder

Ni & WC Mixed Powder

| Alloy | Composition | Size (µm) | HRC | Data Sheet |

|---|---|---|---|---|

| TMPK2130 | TMPN+30WC | -150/+45, -180/+53 | – | – |

| TMPK2135 | TMPN+35WC | -150/+45, -180/+53 | – | – |

| TMPK2140 | TMPN+40WC | -150/+45, -180/+53 | – | – |

| TMPK2145 | TMPN+45WC | -150/+45, -180/+53 | – | – |

| TMPK2150 | TMPN+50WC | -150/+45, -180/+53 | – | – |

| TMPK2155 | TMPN+55WC | -150/+45, -180/+53 | – | – |

| TMPK2160 | TMPN+60WC | -150/+45, -180/+53 | – | – |

Ni & WC Gas Atomized Powder

| Alloy | Composition | Size (µm) | HRC | Data Sheet |

|---|---|---|---|---|

| TMPK2105GA | TMPN+5WC | -53/+10, -45/+10 | – | – |

| TMPK2110GA | TMPN+10WC | -53/+10, -45/+10 | – | – |

| TMPK2115GA | TMPN+15WC | -53/+10, -45/+10 | – | – |

| TMPK2120GA | TMPN+20WC | -53/+10, -45/+10 | – | – |

| TMPK2125GA | TMPN+25WC | -53/+10, -45/+10 | – | – |

| TMPK2130GA | TMPN+30WC | -53/+10, -45/+10 | – | – |

| TMPK2135GA | TMPN+35WC | -53/+10, -45/+10 | – | – |