Home / Products / Investment (Vacuum) Casting

TMetal produces high-precision investment castings with excellent surface fnish and minimal machining needs, reducing cost and lead time. By integrating 3D printing, we deliver complex parts faster and more economically. Alloys include cobalt-, nickel-, and iron-based materials for industries like oil & gas, power, automotive, and petrochemical.

ALLOY CHARACTERISTICS

Nickel-Based Alloys

| Alloy | Typical H.R.C. | Typical U.T.S. KSI | Typical ELONG. % | Application |

|---|---|---|---|---|

| TMPN 50 | 42-58 | 77 | <1 | Wear and corrosion resistance |

| TMPN 60 | 57-62 | 70 | <1 | Extrusion press, screw barrel, pump impeller, plunger |

| TMPN B-2C | 20-25 | 90 | 20 | Resists hot hydrochloric acid |

| TMPN C | 17-27 | 80 | 4 | Hot metal stamping, piercing points, drop forging dies |

| TMPN X | 90 HRB | 55 | 8 | High-temperature and corrosion resistance |

| TMPN T-700 | 42-48 | NA | <1 | High-temperature, wear, and corrosion resistance |

Nickel-Based Super Alloys

| Alloy | Typical H.R.C. | Typical U.T.S. KSI | Typical ELONG. % | Application |

|---|---|---|---|---|

| TMPN 718 | 25 max | 110 | 5 | Vacuum melted high-temperature Ni-based superalloy |

| TMPN 625 | 90 HRB | 85 | 25 | Vacuum melted high-temperature Ni-based superalloy |

Cobalt-Based Alloys

| Alloy | Typical H.R.C. | Typical U.T.S. KSI | Typical ELONG. % | Application |

|---|---|---|---|---|

| TMP 01 | 50-54 | 80 | <1 | Valve seat inserts, bearings, cutter edges |

| TMP 03 | 51-58 | 80 | <1 | High-temperature with severe abrasion |

| TMP 04 | 45-49 | 136 | <1 | Corrosion with erosion on pump parts |

| TMP 06 | 39-43 | 121 | 1 | Some wear and corrosion with ductility |

| TMP 12 | 47-51 | 100 | <1 | High-temperature with wear resistance |

| TMP 19 | 51-53 | 105 | <1 | High-temperature with abrasion |

| TMP 20 | 53-59 | 80 | <1 | Pump sleeves, rotary seal rings, bearing sleeves |

| TMP 21 | 25-30 | 105 | 9 | Good ductility and corrosion resistance |

| TMP 25 | <20 | 134 | 5 | High-temperature nitric acid |

| TMP 31 | 28-35 | 107 | 10 | Aerospace engine parts |

| TMP 250 | 19-29 | 80 | 8 | High-temperature oxidation resistance |

| TMP 694 | 48-54 | 120 | 1 | Gas turbine parts, such as turbine blade interlocks |

| TMP 706 | 39-43 | 116 | 1 | Wear and corrosion with ductility |

| TMP 712 | 47-51 | 121 | <1 | High temperature with wear and corrosion resistance |

| TMP T-400 | 51-58 | 100 | <1 | Good wear and corrosion resistance |

| TMP T-400C | 48-56 | 95 | <1 | Improved oxidation corrosion and abrasion resistance |

| TMP T-401 | 45-50 | 94 | 1 | Enhanced ductility with superior corrosion and wear resistance |

| TMP T-800 | 50-58 | 100 | <1 | High-temperature with severe corrosion, wear, and abrasion |

| UMetal | <25 | 105 | 15 | Valve parts, forging dies, incinerator nozzles |

Iron-Based Alloys

| Alloy | Typical H.R.C. | Typical U.T.S. KSI | Typical ELONG. % | Application |

|---|---|---|---|---|

| TMPF 90 | 51-55 | 65 | <1 | Severe cold abrasion |

| TMPF 02 | 40-44 | 150 | 8 | Nuclear valve trim |

INVESTMENT (VACUUM) CASTING COMPONENTS

Turbocharger Shaft

Material: Cobalt-based Alloy

Size: Custom upon request

Industry: Automotive

Turbocharger Shaft

Material: Cobalt-based Alloy

Size: Custom upon request

Industry: Automotive

Bushing

Material: Cobalt-based Alloy

Size: Custom upon request

Industry: Hot Galvanizing

Connector

Material: Cobalt-based Alloy

Size: Custom upon request

Industry: Power Generation

Glass Mold

Material: Nickle-based Alloy

Size: Custom upon request

Industry: Glass

Glass Mold

Material: Nickle-based Alloy

Size: Custom upon request

Industry: Glass

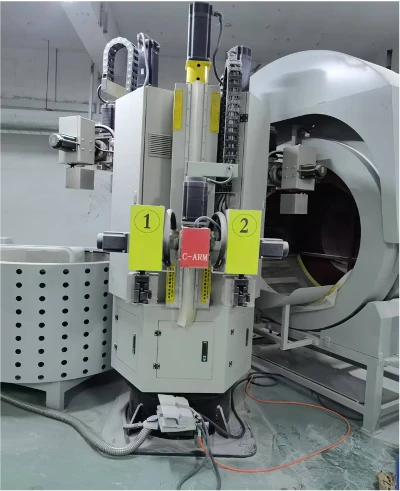

Investment (Vacuum) Casting Production Equipments

Shell-making Robotic Arm

TMetal’s shell-making robotic arm is built for precise investment casting of cobalt and other superalloys. It features a 6-axis vision-guided arm (±50 μm accuracy), climate-controlled coating chambers, multi-layer refractory capability for >1450 °C, and intelligent algorithms for consistent 0.15 ± 0.02 mm coating. Ideal for complex parts like turbine blades and aerospace components. The system’s closed-loop control ensures precise dimensions and shell integrity, keeping defect rates below 0.5%—ideal for superalloy casting.

Automated Dewaxing and Wax Recycling System

Our specialized dewaxing system delivers exceptional performance:

High-pressure steam dewaxing (0.8–1.2 MPa) completes in 6–8 minutes with 99.8% efficiency. A three-stage wax recovery system—primary filtration, molecular sieve (1 μm), and vacuum purification (<50 ppm O2)—restores wax to aerospace-grade purity (≤0.008% ash) for up to 15 reuse cycles. Precision thermal control (±0.5 °C) protects shell integrity.

This integrated system reduces wax consumption by 85–90% while meeting the strict quality standards required for cobalt- and nickel-based superalloy casting.