Home / Products / Engineered Components / Powder Metallurgy and Components

TMetal produces specialized alloy powders for powder metallurgy and manufactures them into functional parts for industries like oil & gas, power, automotive, food machinery, and sawing equipment. With in-house capabilities from R&D to pressing and sintering, we ensure high product quality and reliable delivery.

ALLOY CHARACTERISTICS

Cobalt-Based Alloys

| Alloy | Composition | HRC | g/cm³ | Application |

|---|---|---|---|---|

| TMP 03 | Co-31Cr-13W | 53 | 8.45 | Petrochemical valves, oil well pump, homogenizer |

| TMP 06 | Co-29Cr-4.5W | 40 | 8.3 | Petrochemical valves, homogenizer |

| TMP 12 | Co-30Cr-8.5W | 44 | 8.35 | Petrochemical valves, timber saw tips |

| TMP 20 | Co-34.5Cr-18W | 60 | 8.6 | Oil well pump, homogenizer |

| TMP 20M2 | Co-32Cr-17W | 58 | 8.5 | Oil well pump, homogenizer |

| TMP T-400 | Co-28.5Mo-8.5Cr | 52 | 8.84 | Turbo charger |

P.M. COMPONENTS

Valve Balls & Seats

Material: Cobalt Chrome Alloy

Size: Custom upon request

Industry: Oil & Gas

Stator and Rotor

Material: Cobalt Chrome Alloy

Size: Custom upon request

Industry: Oil & Gas

Sleeve

Material: Cobalt Chrome Alloy

Size: Custom upon request

Industry: Oil & Gas

Seal Ring

Material: Cobalt Chrome Alloy

Size: Custom upon request

Industry: Oil & Gas

Valve Cage

Material: Cobalt Chrome Alloy

Size: Custom upon request

Industry: Oil & Gas

Valve Balls

Material: Cobalt Chrome Alloy

Size: Custom upon request

Industry: Oil & Gas, Bearing

ALLOY CHARACTERISTICS

| Alloy | HRC | |

|---|---|---|

| TMP 01 | TMetal 01 has a higher proportion of primary carbides dispersed in the alloy and is therefore harder than TMetal 12. TMetal 01 is appropriate for use when cutting harder species and is available in spooled wire form. | 58 |

| TMP 12 | TMetal 12 is a weldable alloy composed of cobalt, chrome, and tungsten with high toughness and excellent corrosion resistance, and appropriate for use in circular and band saws when cutting green, frozen, and kiln-dried lumber. | 48 |

Cobalt-Based Alloys

| Alloy | Composition | HRC | g/cm³ | Application |

|---|---|---|---|---|

| TMP 03 | Co-31Cr-13W | 53 | 8.45 | Petrochemical valves, oil well pump, homogenizer |

| TMP 06 | Co-29Cr-4.5W | 40 | 8.3 | Petrochemical valves, homogenizer |

| TMP 12 | Co-30Cr-8.5W | 44 | 8.35 | Petrochemical valves, timber saw tips |

| TMP 20 | Co-34.5Cr-18W | 60 | 8.6 | Oil well pump, homogenizer |

| TMP 20M2 | Co-32Cr-17W | 58 | 8.5 | Oil well pump, homogenizer |

| TMP T-400 | Co-28.5Mo-8.5Cr | 52 | 8.84 | Turbo charger |

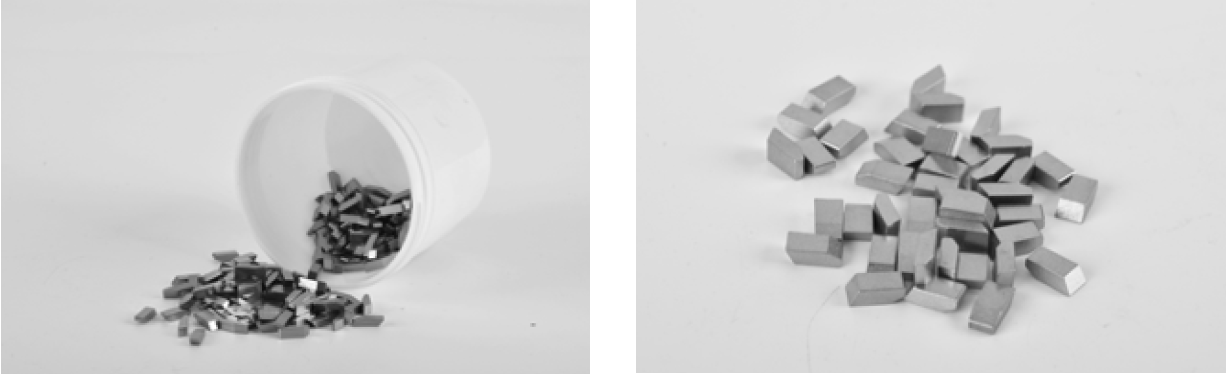

Saw Tips

Material: Cobalt Chrome Alloy

Process: Powder Metallurgy

HRC: 44-49

Size: Custom upon request

Blades

Material: Cobalt Chrome Alloy

Process: Powder Metallurgy

HRC: 45-50

Size: Custom upon request

P.M. PRODUCTION EQUIPMENTS

6MPa Vacuum Pressure Sintering Furnace

Machining Center

Automatic Press Machine

Ball Grinder