Spinner

- Material: Cobalt Chrome Alloy

- Process: Investment Casting

- Density:8.4 g/cm ³

- Size: ⌀200-500 mm or Custom upon request

- Hole size: ⌀ 0.5-1.0mm

- Operating Temperature: 1050 °C

- Rotating Speed: ≤3000 r/min

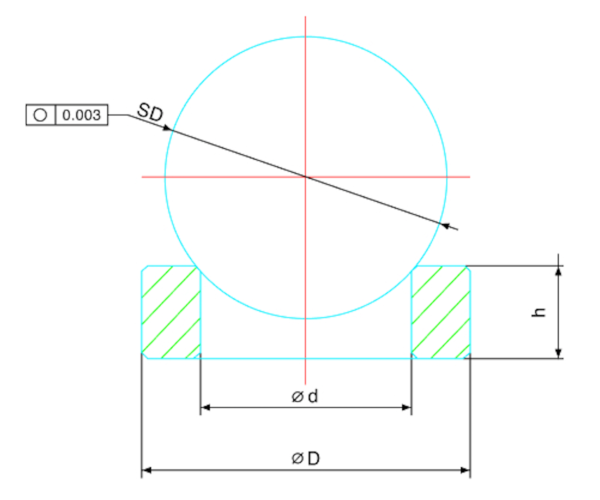

| Dimension | V11-106 | V11-125 | V11-150 | V11-175 | V11-225 | V11-250 | V11-375 |

|---|---|---|---|---|---|---|---|

| SD (mm) | 15.875 | 19.05 | 23.8125 | 28.575 | 34.925 | 42.8625 | 57.15 |

| D (mm) | 20.142 | 23.317 | 29.667 | 35.255 | 43.688 | 51.054 | 78.029 |

| d (mm) | 11.89 | 14.61 | 17.83 | 21.08 | 26.57 | 32.13 | 44.5 |

| h (mm) | 12.7 | 12.7 | 12.7 | 12.7 | 12.7 | 12.7 | 19.05 |

Department of Materials Science & Engineering

Department of Mechanical & Aerospace Engineering